| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Cell Instruments

Model Number : CLRT-01

Certification : CE

Place of Origin : China

MOQ : 1 Set

Price : GET AN OFFER

Payment Terms : L/C, T/T

Supply Ability : 100 Sets/Week

Delivery Time : 3 days

Packaging Details : Plywood Carton

Test Range : 0~1MPa

Resolution : 0.1 ℃

Shaking Speed : Adjustable

Piercing Speed : 5mm/s (other available)

Sample Height : ≤ 350mm (other available)

Temp. range : 0 ~ 30 ℃

Shaking time : 40s (other available)

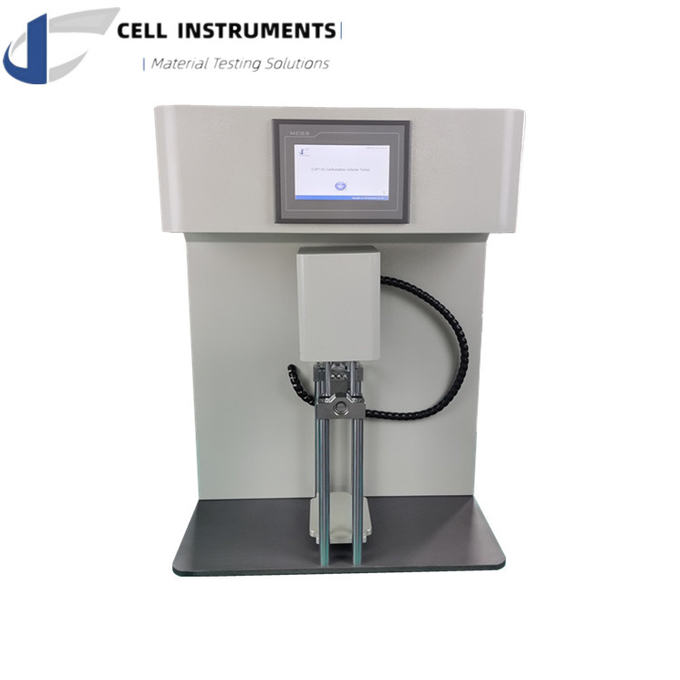

Introducing the CLRT-01 Carbonation Tester: An Advanced Solution for Beverage Quality Analysis

The CLRT-01 Carbon Dioxide Volume Tester, engineered by Cell Instruments, stands as a pioneering innovation tailored to evaluate CO2 volume in beverages with unparalleled precision and efficiency. Crafted to meet the exacting standards of the beverage industry, this automated tester revolutionizes the assessment of carbonation levels, facilitating enhanced product quality and consumer satisfaction.

Automation Revolutionized: The CLRT-01 streamlines the testing process through automation, eliminating manual errors and boosting operational efficiency, a significant leap from traditional methodologies.

Precision Redefined: Under the meticulous control of an industrial-grade PLC system, our tester ensures utmost precision in pressure and temperature measurements, guaranteeing reliable and consistent results essential for quality assurance.

Versatility Personified: Designed to accommodate a wide range of packaging formats including bottles and cans, the CLRT-01 offers unmatched flexibility in carbonation volume assessment, catering to diverse industry needs.

Tailored Customization: With customizable shaking parameters, such as frequency and duration, manufacturers can fine-tune the testing process to align with specific product formulations and quality standards, ensuring optimal performance.

Real-time Monitoring: Equipped with high-precision sensors, our tester enables real-time monitoring of pressure and temperature, facilitating immediate adjustments and ensuring the accuracy of results throughout the testing process.

Quality Assurance Elevated: By automating CO2 volume assessment, our tester guarantees consistent carbonation levels, thereby upholding the highest standards of beverage quality and ensuring consumer satisfaction.

Enhanced Efficiency: The streamlined testing sequence not only saves valuable time but also reduces reliance on manual labor, leading to increased productivity and cost-effectiveness in production.

Compliance Assured: The CLRT-01 adheres to renowned standards such as ASTM F1115 and GB T10792, providing manufacturers with confidence in meeting industry benchmarks and regulatory requirements.

The primary function of the CLRT-01 Carbonation Tester is to offer a sophisticated and automated method for evaluating carbon dioxide volume in beverages. By establishing a precise correlation between pressure and temperature, our tester empowers manufacturers to maintain product consistency and deliver beverages that epitomize excellence in taste and effervescence. With applications spanning the beverage industry, our tester serves as an indispensable tool in ensuring the quality and integrity of drinks across various packaging formats.

| CLRT-01 CO2 Volume Tester | |

| Test Range | 0~1MPa |

| Resolution | 0.01KPa |

| Shaking Speed | Adjustable |

| Piercing Speed | 5mm/s (other available) |

| Sample Height | ≤ 350mm (other available) |

| Temp. range | 0 ~ 30 ℃ |

| Shaking time | 40s (other available) |

| Resolution | 0.1 ℃ |

|

|

Plastic Beverage Container Carbon Dioxide (CO2) And Pressure Loss Testing Instrument ASTM F1115 CO2 Volume Tester Images |