| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : China

Brand Name : Cell Instruments

Model Number : GHS-01

Packaging Details : Plywood Carton

Delivery Time : 3~5 days

Payment Terms : TT, LC

Supply Ability : At Stock

MOQ : 1 SET

Certification : CE

Price : Get An Offer

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

The Heat Seal Test apparatus is a specialized instrument designed to help laboratories, manufacturers, and researchers accurately evaluate the sealing performance of various packaging materials. This device is essential for determining the optimal sealing parameters, including temperature, time, and pressure, to ensure that materials such as films, laminates, composites, and polymers achieve the best possible heat-sealed performance. Whether you're working in the food, pharmaceutical, beverage, or packaging industry, the Heat Seal Test apparatus offers reliable data to enhance your product quality and meet industry standards.

The Heat Seal Test is an essential procedure for evaluating the heat sealability of flexible packaging materials. Heat sealing is a critical process in industries such as food and beverage, pharmaceuticals, and consumer goods, as it ensures product integrity, safety, and shelf life. The Heat Seal Test apparatus is designed to simulate production sealing conditions in a controlled environment, allowing companies to optimize their sealing processes and produce packaging that meets stringent quality requirements.

This versatile testing instrument is designed for use in quality control labs, research facilities, and production lines, offering detailed insights into how materials behave under different sealing conditions. With customizable sealing jaws, independent upper and lower jaw heating, and precise control of temperature, dwell time, and pressure, the Heat Seal Test apparatus is the ultimate solution for sealing performance testing.

Five Sealing Temperatures in One Test: The Heat Seal Test apparatus can evaluate up to five different sealing temperatures in a single test cycle, streamlining the process and providing a comprehensive understanding of how materials perform under varying conditions.

Precise Dwell Time and Pressure Control: The apparatus includes proximity and pressure sensors that ensure accurate control of the sealing process, reducing variability and ensuring consistent results.

P.I.D. Temperature Control: Equipped with Proportional-Integral-Derivative (P.I.D.) technology, the Heat Seal Test apparatus maintains precise control over the sealing temperature, eliminating fluctuations that could affect the test outcomes.

Uniform Heating Across Sealing Jaws: The aluminum-encapsulated sealing jaws provide uniform heating, ensuring that no inhomogeneous heating affects the sealing quality. This uniformity is critical in ensuring that seals are consistent and strong across the entire material surface.

Independent Upper and Lower Jaw Heating: The Heat Seal Test apparatus offers independent heating for the upper and lower sealing jaws, enabling users to test multi-layer materials and customize heat application for each layer of the sample.

Customizable Sealing Jaws: This apparatus is designed with flexibility in mind. Users can customize the dimensions, shape, and surface of the sealing jaws to accommodate different material types and test specifications.

The Heat Seal Test apparatus is widely used in industries that require reliable packaging solutions. Some key industries and applications include:

Food products rely heavily on secure seals to maintain freshness, prevent contamination, and extend shelf life. The Heat Seal Test apparatus allows manufacturers to test and optimize the heat sealing parameters for a variety of packaging materials such as polyethylene, polypropylene, and multi-layer laminates. Accurate testing ensures that the packaging material can withstand different production environments and storage conditions.

In the pharmaceutical industry, secure seals are vital for maintaining product safety and efficacy. Packaging materials used for pharmaceutical products must meet strict regulatory standards to ensure that they can preserve the integrity of the contents. The Heat Seal Test apparatus helps pharmaceutical manufacturers evaluate the heat sealability of blister packs, vials, and medical-grade films, ensuring compliance with regulatory requirements.

Beverage containers, especially flexible pouches, need to be sealed tightly to prevent leakage and contamination. The Heat Seal Test ensures that the sealing parameters are precisely controlled, delivering durable seals that protect the product from external elements while maintaining the quality of the beverage.

Medical device packaging requires stringent testing to ensure sterility and prevent contamination. The Heat Seal Test apparatus is used to evaluate the heat sealability of sterile barrier systems, ensuring that the materials can maintain a secure seal throughout the product's lifecycle.

From cosmetics to household products, consumer goods packaging must provide secure seals to protect products from damage, leakage, or tampering. The Heat Seal Test apparatus allows companies to fine-tune the sealing process for plastic films, laminates, and other flexible materials, ensuring that packaging meets consumer expectations and industry standards.

The Heat Seal Test process involves applying controlled heat and pressure to a test material for a specified amount of time. The goal is to simulate the sealing conditions used in actual production environments to determine the material's heat sealability.

Using the Heat Seal Test apparatus, users can adjust the following parameters to ensure optimal seal quality:

The Heat Seal Test apparatus is built to comply with international standards for heat sealing testing. This ensures that your testing processes meet industry best practices and regulatory requirements. The relevant standards include:

Investing in the Heat Seal Test apparatus provides several key benefits for manufacturers, quality control labs, and research institutions:

For optimal performance, regular maintenance and calibration of the Heat Seal Test apparatus are essential. This includes routine checks of the heating elements, pressure sensors, and sealing jaws to ensure consistent results. Calibration should be performed according to the manufacturer's guidelines to maintain accuracy and compliance with industry standards.

The Heat Seal Test is a critical component of packaging quality control. Whether you're producing food packaging, pharmaceutical products, or consumer goods, ensuring that your materials are properly sealed can prevent product loss, contamination, and customer dissatisfaction. The Heat Seal Test apparatus provides precise, reliable data to optimize your sealing processes, helping you meet industry standards and maintain the highest levels of product integrity.

|

|

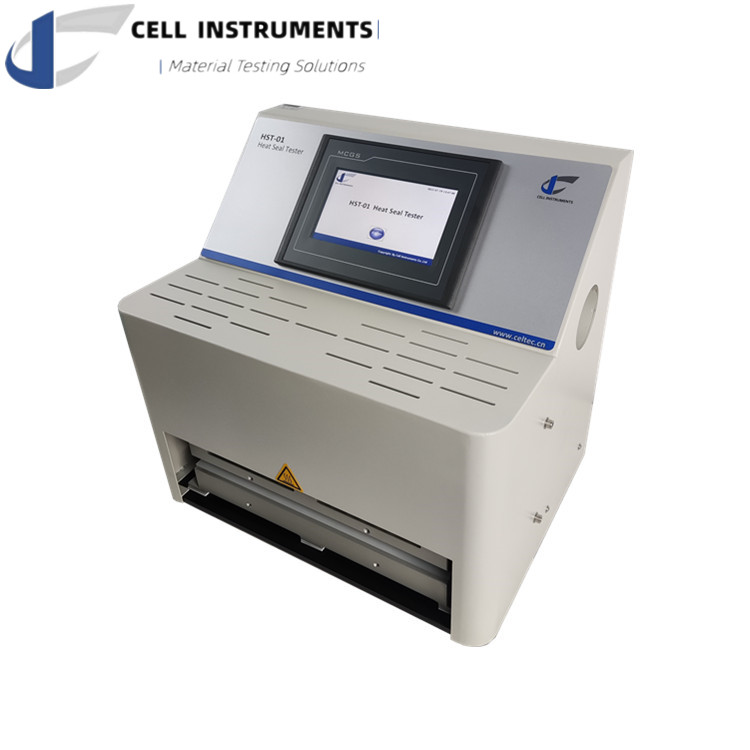

Heat Seal Test Apparatus Polyer Film Heat Sealer Lab Use Images |